Micron Precision Metrology Compounds for Quality Control. Trusted in the most demanding fields: [Aerospace|Formula 1|Energy|Engineering|Automotive|Medical]

How Does Plastiform Work?

Prepare the part

Ensure your subject part is clear and free of swarf, oil and dirt. Use the Plastiform AC-019 to assist in the process.

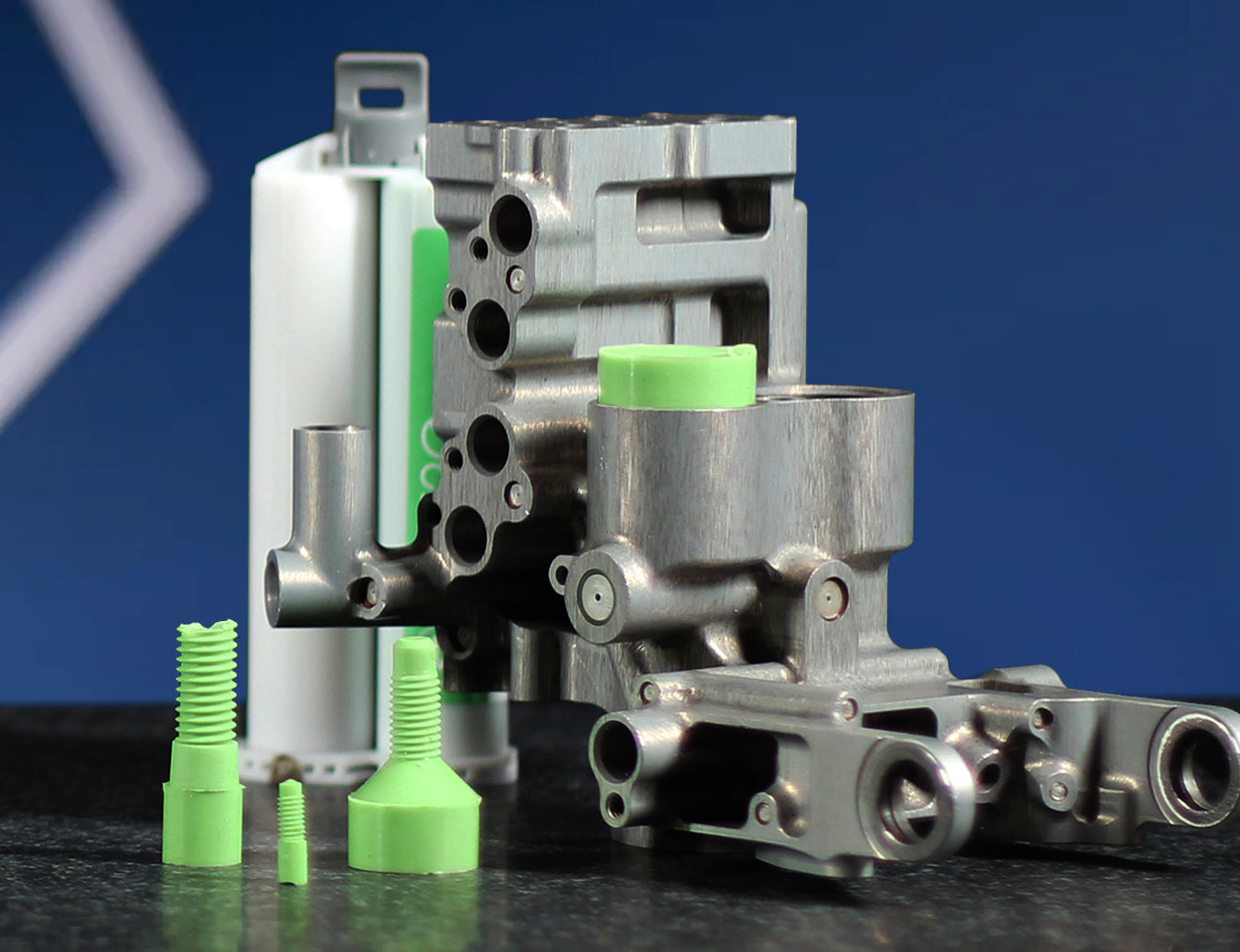

Apply the Compound

Using the simple, Nozzle, Cartridge and Gun system Plastiform is applied to the subject part.

Allow to cure

Curing takes around 6-8 Minutes for our most popular products. But certain products can be as fast a 60 seconds.

Remove the impression

Remove the impression from the part. The impression will replicate the subject part with Micron accuracy while leaving no residue

Inspect with Micron Accuracy

Typically measured using a profile projector or shadow graph the impression is easily inspected. Using the AC-012 it is also possible to slice the impression on certain products.

With Plastiform you can [Expand your measurement capabilities|Increase your inspection efficiency|Inspect with Micron Accuracy]

Questions?

Our cartridge based system carries Micron Accuracy

Plastiform is best measure using an optical or vision system. This is made easier using the AC-012 Double blade cutter.

Plastiform is simple and easy to use - after a few minutes you'll feel comfortable using our systems.

Plastiform products are non-toxic and can be handled without PPE.

No substances / raw materials containing substances mentioned in the REACH SVHC list in a concentration > 0.1 % are present in the composition of Plastiform products.